COM Express Basic TYPE 7 AND TYPE 6 MODULES PORTWELL

Price 29500.00 INR/ Piece

COM Express Basic TYPE 7 AND TYPE 6 MODULES PORTWELL Specification

- Finish

- Solder mask, matte top, optional conformal coating

- Mounting Type

- Board-to-board mounting with standoff and screws

- Process

- Multi-layer PCB fabrication, component mounting, QA testing

- Tolerance

- PCB thickness tolerance: 0.1 mm

- Material

- High quality PCB, electronic components, metallic heatspreader

- Supply Voltage

- Voltage Input: 12V DC (typical)

- Application

- Industrial automation, military, medical, networking, transportation

- Temperature

- Operating: -40C to +85C (industrial grade); Storage: -40C to +85C

- Standard

- PICMG COM Express R3.0

- Input Voltage

- 12V DC

- Installation Guideline

- Install onto carrier board via high-speed board-to-board connectors according to COM Express specification

- Design

- COM Express Basic TYPE 6/7 compliant

- Surface Treatment

- OSP/ENIG/Lead-free finish, gold finger contacts

- Size

- Basic form factor 125 mm x 95 mm

- Humidity

- 0%90% non-condensing

- Technique

- SMT, Through-hole, Reflow soldering

- Service Period

- 24/7 operation, long life cycle support

- Color

- Green (PCB), With aluminum heatspreader

- Processing

- Surface mount technology, precision assembly

- Output Voltage

- 3.3V, 5V, 12V to carrier board (signals only)

- Thickness

- PCB: 1.6 mm, Heatspreader: 3 mm

- Usage

- Industrial embedded computing, edge servers, networking

- Product Type

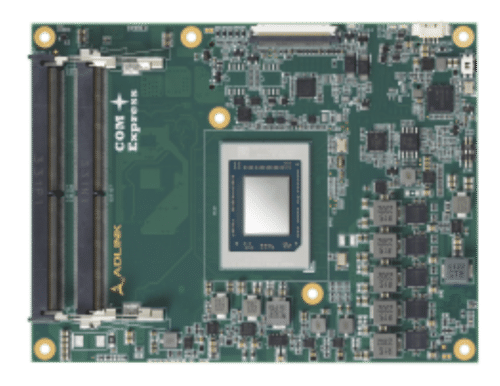

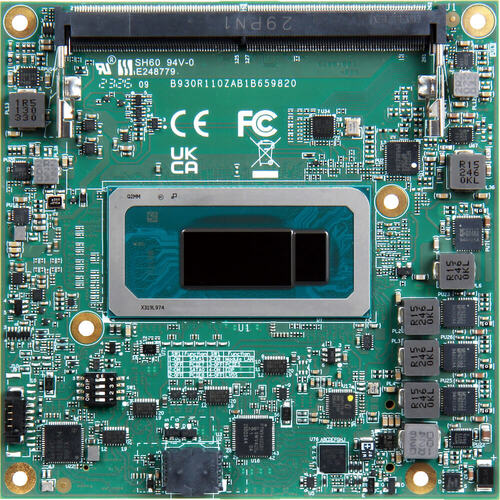

- COM Express Basic Module TYPE 6 & TYPE 7

- Weight

- Approx. 300g (with heatspreader)

- IP Rating

- Not IP rated; recommended for use in enclosures

- Dimension (L*W*H)

- 125 mm x 95 mm x 13 mm (typical with heatspreader)

- Equipment Type

- Modular embedded computer module

- Frequency

- Supports up to Intel Xeon/ Core i7 CPU frequencies (varies per model)

- Processor Support

- Up to Intel Xeon, Core i7/i5/i3, Atom, or compatible (model dependent)

- Display Interface

- TYPE 6: 3x DDI/HDMI/DisplayPort, LVDS/eDP; TYPE 7: No onboard graphics

- Power Management

- ACPI 5.0 compliant, hardware monitoring features

- Cooling

- Passive heatspreader; active cooling optional by design

- Memory Support

- Up to 64GB DDR4 SO-DIMM/ECC (model dependent)

- Storage Interface

- 2 x SATA III, eMMC (optional, type dependent)

- Expansion Interface

- PCI Express Gen3, SATA III, USB 3.0/2.0, LPC, I2C, SMBus

- BIOS/UEFI

- Insyde/AMI BIOS with customization support

- Carrier Board Compatibility

- Compatible with standard COM Express Basic Type 6/7 carrier boards

- Shock & Vibration

- IEC 60068-2-27/6 compliant (when properly mounted)

- Ethernet Ports

- Up to 4 x 10GbE (TYPE 7), up to 1 x GbE (TYPE 6)

- Watchdog Timer

- Supported (model and software dependent)

- Operating System Support

- Windows, Linux, VxWorks, QNX (depends on carrier board drivers)

- Compliance

- RoHS, REACH, CE, UL (certification may depend on build)

COM Express Basic TYPE 7 AND TYPE 6 MODULES PORTWELL Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 500 Pieces Per Month

- Delivery Time

- 15 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About COM Express Basic TYPE 7 AND TYPE 6 MODULES PORTWELL

COM Express Basic (125 x 95mm): COMe basic size form factor (125 x 95mm) and types 6 and 7 pin out COM Express Type 7The Type 7 COM-Express module is designed for server-grade applications that require high-speed data and network throughput. It does this by replacing all of the audio and graphics interfaces while reducing the number of SATA ports and USB 2.0 signals and replacing them with 8x PCIe lanes and 4x 10Gb Ethernet ports.

COM Express Type 6The Type 6 COM-Express module is defined by PCI Industrial Computer Manufacturers Group (PICMG). The Type 6 COM-Express provides standardized module interfaces including storage, graphic control, video Interfaces (LVDS, VGA & DDI), and USB 3.0 to meet different application requirements from the various vertical markets.

Advanced Processor and Memory Performance

COM Express Basic Type 6/7 modules from Portwell support processors up to Intel Xeon and Core i7, delivering outstanding computational power for data-intensive and industrial tasks. Models accommodate up to 64GB DDR4 SO-DIMM/ECC memory, ensuring reliable performance even during critical operations. This allows seamless multitasking and rapid response times for applications in automation, networking, and servers.

Versatile Networking and Expansion Capabilities

Type 7 modules provide up to 4 x 10GbE Ethernet ports for high-throughput networking, whereas Type 6 includes up to 1 x GbE for broad connectivity options. Integrated PCI Express Gen3, SATA III, and multiple USB interfaces support flexible system expansion, while compliance with PICMG COM Express R3.0 facilitates easy integration into standardized carrier boards.

Rugged Design for Industrial Applications

Designed with a robust multilayer PCB, quality components, and a metallic heatspreader, Portwell modules offer long-term durability. They comply with key industry standards including IEC 60068-2-27/6 for shock and vibration, and support an operational temperature range from -40C to +85C, making them suitable for harsh industrial environments. Optional conformal coating and passive or active cooling ensure reliable operation under varied conditions.

FAQ's of COM Express Basic TYPE 7 AND TYPE 6 MODULES PORTWELL:

Q: How do I install a Portwell COM Express Basic Type 6 or Type 7 module?

A: Installation is performed by mounting the module onto a compatible carrier board using board-to-board connectors, standoffs, and screws, following the COM Express specification. This ensures secure connectivity and reliable performance in embedded systems.Q: What are the main differences between Type 6 and Type 7 Portwell COM Express modules?

A: Type 6 modules offer onboard graphics and support various display interfaces (DDI/HDMI/DisplayPort, LVDS/eDP), with up to 1 x GbE Ethernet, suited for multimedia and general-purpose computing. Type 7 modules focus on networking, featuring up to 4 x 10GbE ports and no onboard graphics, ideal for edge servers and high-bandwidth applications.Q: When should I consider using these modules for industrial applications?

A: Portwell Type 6 and Type 7 COM Express modules are well-suited for industrial automation, military, medical, networking, and transportation sectors where reliability, long life cycle support, and 24/7 operation are required. Their rugged design, wide temperature range, and robust networking interfaces make them ideal for demanding environments.Q: Where are these modules typically deployed?

A: These modules are commonly used in embedded computing systems for factory automation, edge server installations, military and medical devices, and networking infrastructure. Their modularity and compliance with standard carrier boards allow flexible integration into various system architectures.Q: What benefits does the ECC memory support provide?

A: ECC (Error Correcting Code) memory helps detect and correct memory errors, which enhances system reliability and data integrity-crucial in industrial, medical, and mission-critical environments where uninterrupted operation is essential.Q: How does the module manage power and ensure system stability?

A: With ACPI 5.0 compliance and hardware monitoring features, the module supports advanced power management, efficient energy use, and system stability. The integrated watchdog timer further guards against system failures by enabling automatic resets if required.Q: What is the process for ensuring product quality and durability?

A: Portwell uses state-of-the-art manufacturing techniques, including surface mount technology, multi-layer PCB fabrication, precision component mounting, and comprehensive QA testing, to ensure each module meets stringent industrial standards for reliability and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Grade Motherboard Category

ISA-2 631

Price 27000.0 INR / Piece

Minimum Order Quantity : 10 Pieces

Product Type : ISA2 631

Size : Customizable

Process : Hot Rolled

Dimension (L*W*H) : As Per Requirement

ATX Industrial Mother Board 8th Gen Xeon E and Core i7 i5 i3 IBASE

Minimum Order Quantity : 1 Unit

Product Type : ATX Industrial Mother Board 8th Gen Xeon E and Core i7 i5 i3 IBASE

Size : Different Size

COM Express Compact Type 6 PORTWELL

Price 29500 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : INDUSTRIAL MOTHERBOARD

Size : 95*95MM

Process : Intel Tiger LakeUP3 Core Processor Intel Core Whiskey LakeU i7/i5/i3 series

Dimension (L*W*H) : 95*95 Millimeter (mm)

PICMG 1.3 HALFSIZE SERIES SINGLE BOARD COMPUTERS

Price 15000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : INDUSTRIAL MOTHERBOARD

Size : 167.64 x 126.39mm

Process : Intel Core i3/i5/i7/i9/ Pentium/ Celeron

Dimension (L*W*H) : 167.64 x 126.39mm Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS